Inspections Just Got an Upgrade: How MCP, A2A, and Low-Code Tech Are Fixing the Most Boring Job on Earth

Inspections Just Got an Upgrade: How MCP, A2A, and Low-Code Tech Are Fixing the Most Boring Job on Earth

When people hear “inspection,” no one jumps out of their seat yelling “Yes! Paperwork and checklists!” Most inspections are somewhere between necessary evil and slow-moving disaster. You’ve got sensors throwing alerts, legacy systems not talking to each other, inspectors juggling clipboards like it’s 1997, and processes that seem custom-designed to make you cry.

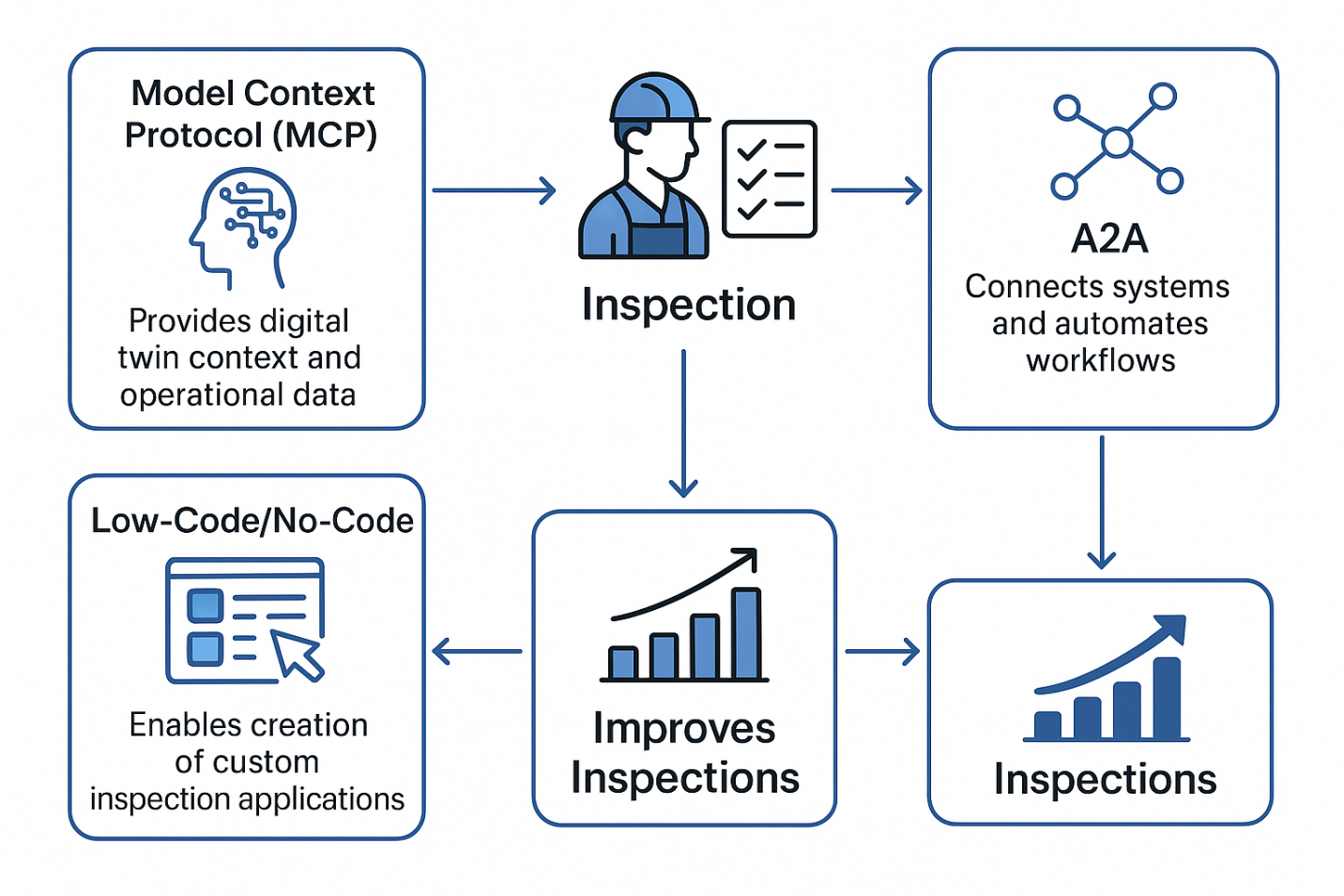

But here’s the plot twist: there’s a way to make inspections faster, smarter, and actually helpful, using the power of three modern technologies—Model Context Protocol (MCP), Application-to-Application Integration (A2A), and Low-Code/No-Code (LCNC) platforms.

This is not a buzzword salad. It’s a recipe for turning inspections from time-wasters into strategic assets.

Part 1: MCP – The Digital Twin Whisperer

Let’s start with MCP, or Model Context Protocol.

MCP is like that one person in every office who knows everything—except it’s about machines, parts, and their digital twins. It connects real-world assets to their digital counterparts, and ensures any app or system that accesses that data sees it the same way, in the right context.

So if you’re inspecting a pump, MCP tells you:

- The pump’s exact model

- Its history of failures (spoiler: it’s dramatic)

- Environmental data

- Connected systems it impacts

It’s like arriving to inspect something and getting a full Netflix recap: “Previously on ’The Sad Saga of Pump #17’…”

This isn’t just nice to have. It lets inspectors make better decisions, faster, with full visibility into what they’re dealing with—no guessing, no wasted time.

Part 2: A2A – The Silent Workhorse

Now enter A2A, or Application-to-Application integration. This is the part that makes your systems talk to each other without needing a team of overworked humans doing copy-paste gymnastics.

Imagine this:

- A sensor detects a spike in vibration.

- A2A pushes that alert into your CMMS (maintenance system).

- It creates an inspection task, notifies the right person, and updates your scheduling system.

- All automatically. No phone calls. No emails that go unread. No “Who was supposed to handle this?”

This is where inspections start to feel like a real-time operation, not a 3-day lag followed by a last-minute scramble.

Part 3: LCNC – The Inspector’s Secret Weapon

Finally, let’s talk about Low-Code/No-Code (LCNC) platforms. If MCP is the brain and A2A is the bloodstream, LCNC is the hands—the thing you use to actually build and customize your inspection workflows, even if your coding skills are limited to copying error messages into Google.

Here’s what LCNC brings to inspections:

- Custom apps: Want a mobile inspection form that includes photos, checklists, and voice notes? Build it in a morning.

- Workflow automation: Have inspections trigger follow-up tasks, emails, or even drone dispatches. (Okay, maybe not drones—yet.)

- Rapid updates: Change inspection forms on the fly. Add new steps. Swap out an approval flow. Zero dev time needed.

And yes, it makes your inspectors look like tech wizards, which is always a plus.

Putting It All Together: The Inspection Dream Team

Let’s walk through a real-world scenario:

- A sensor detects something sketchy. Maybe a pressure reading that’s a bit too spicy.

- A2A jumps into action. A work order is automatically created and routed to the inspection team.

- MCP adds the brainpower. It attaches the full context—equipment history, location data, environmental variables, and even the digital twin model.

- LCNC powers the field tools. The inspector receives a mobile app (custom-built with LCNC) that includes everything they need: digital checklist, real-time data, step-by-step guidance, and a big shiny “Submit” button.

- Inspection done. The results are pushed back to the system via A2A, dashboards are updated, alerts sent, and future maintenance adjusted based on the findings.

No delays. No paperwork mountains. No “Hey, did anyone ever check that thing?” moments.

Why It Matters (and Why You Should Care)

Let’s break it down:

| Traditional Inspections | With MCP + A2A + LCNC |

|

Manual logging |

Automated workflows |

| Siloed systems | Seamless data flow |

| Guesswork decisions | Real-time insights |

| One-size-fits-all tools | Custom inspection apps |

| Paper everywhere | Digital everything |

When you adopt this trio, you go from reactive firefighting to proactive optimization. You’re no longer just “checking boxes”—you’re building an ecosystem that learns, adapts, and improves.

Final Thoughts: The Inspections Glow-Up

In the old world, inspections were a chore. In the new world, they’re a strategic advantage.

With:

- MCP giving you complete digital context,

- A2A automating your backend like a backstage crew on Red Bull,

- LCNC empowering your team to build what they need without begging IT,

…you’re transforming inspections into something smarter, faster, and actually kinda fun.

Well, maybe not fun-fun. But definitely more satisfying than wrangling a malfunctioning clipboard at 6 AM.