Facilitating Oil & Gas industry perform safety inspections

Oil and gas safety inspections plays a critical part in maintaining safety and sustainability in the industry.

These inspections ensure identifying and preventing environmental damage risk, financial losses, legal consequences, and threats to the life forms on the Earth. An inadequate inspection can lead to environmental hazards such as leaks, spills, and accidents, with severe repercussions for the environment and communities. These risks can be mitigated by prioritizing thorough inspections, the industry can uphold its responsibilities by avoiding costly incidents and ensuring the well-being of both its employees and the environment.

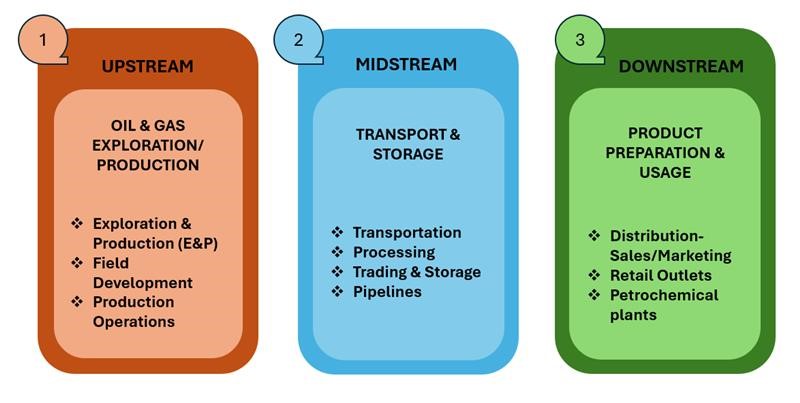

For Oil & Gas domain these inspections are critical across the value chain of the industry. There is need to have inspection across Upstream, Midstream and Downstream processes for Oil & Gas domain. Starting from exploration, field development, transportation, processing and storage till refining, wholesale and retail inspections plays a crucial role in meeting industry demands, streamlining processes, enhancing performance, and shaping a safer, more compliant, and environmentally responsible future.

Introducing aHawkAI

aHawkAI is a SaaS-based enterprise-level inspection solution developed by Aaseya. It is designed to streamline and improve the inspection processes. aHawkAI offers a set of features required to enhance the Inspection processes, making it an invaluable tool for the Oil & Gas Safety Inspections.

Core Features of aHawkAI

- Customizable Forms and Checklists: Tailored inspection checklists to meet specific industry and specific Inspection type needs.

- Mobile Accessibility: Conduct inspections on mobile devices such as smartphones and tablets, which makes the product more accessible and handier to be used on-sites.

- Optimized Routing: Google maps integration providing the most optimum route considering one to many sites at once, to the Inspection agents for navigating to the Inspection sites.

- Intelligent Work Assignment: Inspector’s capacity and skill-based work allocation for better productivity.

- Seamless Integration: Ability to connect with other software systems for smooth data flow and interoperability.

- Guided Workflows: Provides step-by-step navigation for consistent and accurate inspections.

- Low Code Platform: Accelerate development and deployment of customized inspection solutions.

How aHawkAI enables Inspections in Oil & Gas Industry?

The advanced features of aHawkAI ensures that all the aspects of Inspections are covered End-to-End. Starting from data setup, Inspection creation, allocation, tracking and report generation, aHawkAI empower organizations to perform effective inspections that enhance accuracy, efficiency, and compliance. Here’s how:

- Customizable Forms and Checklists: This ensure all relevant data is captured and tailored to specific inspection needs. For example, an inspector can use a checklist specifically designed for Oil & Gas related Inspections, ensuring nothing is overlooked.

- Mobile Accessibility & Real-Time Data Capture: The inspectors can conduct thorough inspections on-site using mobile devices. For instance, Inspector may conduct Inspection of petroleum storage tank where there are visible signs of damage on the outer surface. He can easily capture detailed notes and upload pictures of the damage in real-time using his hand-held device. This capability ensures a comprehensive and immediate overview of the inspection site, allowing for prompt identification and rectification of any potential hazards.

- Optimized Routing: Planning the day ahead by looking at the Inspection sites like fuel stations in an area on Google map by using the optimized route feature. This can help Inspectors plan their day better.

- Intelligent Work Assignment: Picking the best suited Inspector to perform the Inspections by looking at their skill and availability is one of the outstanding features of aHawkAI.

Let us explore how we can perform an Inspection at an Oil Refinery using aHawkAI’s seamless setup.

There are various safety hazards in oil refineries that can pose risks to both workers and assets. Here are some common hazards like fire and explosion, toxic chemicals and gases, corrosiveness and asphyxiation due to gas leakages. Here is how aHawkAI’s features and flexibility can facilitate users to configure and setup the correct Inspection data.

Inspection Type & Skill configuration: User can identify and configure Equipment Inspection as an Inspection type. There is a need to configure required skills set of the Inspectors which can be for example a certification in equipment inspection or any field training. This makes sure that the right set of Inspectors are assigned for performing the refinery Equipment Safety Inspection task.

Checklist Management: User can configure the checklist for safety inspection like keeping check on the equipment’s condition, check for clean flame sensor, burners conditions, check for any visible signs of corrosion etc. This makes sure that all the safety aspects are covered in the Inspection by the Inspector.

Zone Management: The capability to define physical areas on maps helps mapping the oil refinery to a specific zone. These zones can be mapped to specific users for a better distribution of work using the aHawkAI’s intelligent algorithm.

Entity & User Management: User can then onboard the Oil Refinery into aHawkAI by capturing the required details. They then configure the users like Inspectors, Inspector Managers, Approvers etc. Tagging them to zones, safety inspection and safety inspection skills, help to assign the right Inspector for performing the Inspection.

Conclusion

The aHawkAI can revolutionize the inspection process of any Oil & Gas stream with its advanced features, enabling organizations to configure data the way they want for conducting the inspections. Through features like customizable forms, mobile accessibility, and optimized routing and Intelligent work assignment, aHawkAI provides a comprehensive solution that makes the Inspection process more efficient and complete.

Understanding the importance of Inspections in an Oil & Gas context and utilizing advanced tools like aHawkAI allows us to create safer environments.